Qais (pronounced “Case”) Arabo got his start in 1995 at a mall kiosk with his first single-head Tajima embroidery machine, making customized baseball caps for shoppers. But his Knoxville, Tennessee-based Classic Print Company has evolved tremendously since then. As customers requested items he didn’t offer, like embroidered polos, he said “yes” to the orders anyway and learned how to do it. As his business took off, he was embroidering around the clock from the time the mall’s doors opened to the time they closed, and then even through the night to complete orders. Soon, customers requested screen printed T-shirts, so he began subcontracting to a local printer. He continued to expand his business over the years to a new location and more.

He currently offers heat transfers and sewing in-house while outsourcing embroidery, screen print and direct-to-garment, though he formerly offered more methods in-house. But Classic Print Company’s in-house capabilities have shifted over the years to meet Arabo’s business goals. Regardless of whether it’s offered in-house or outsourced, decoration continues to play an important role in his business.

“Offering custom decoration is a service, and you charge for that service, so it has helped us charge a fee for the finished product,” he said. “The more complex or the more detail your decoration is the more you can charge for it. … People can’t just go out and buy an embroidery machine to embroider 12 polo shirts for their lawn company. No, they come to a professional that has the right equipment and pays for that service. So offering different decoration methods has helped us retain clients and [upsell].”

For the first installment of Decoration Diaries, Arabo tells us how his company completed a complex jacket decorating job for a luxury department store with its in-house screen printing and sewing capabilities, and in the process overcame dye migration, the reaction of fabric dye bleeding into the imprint ink during curing.

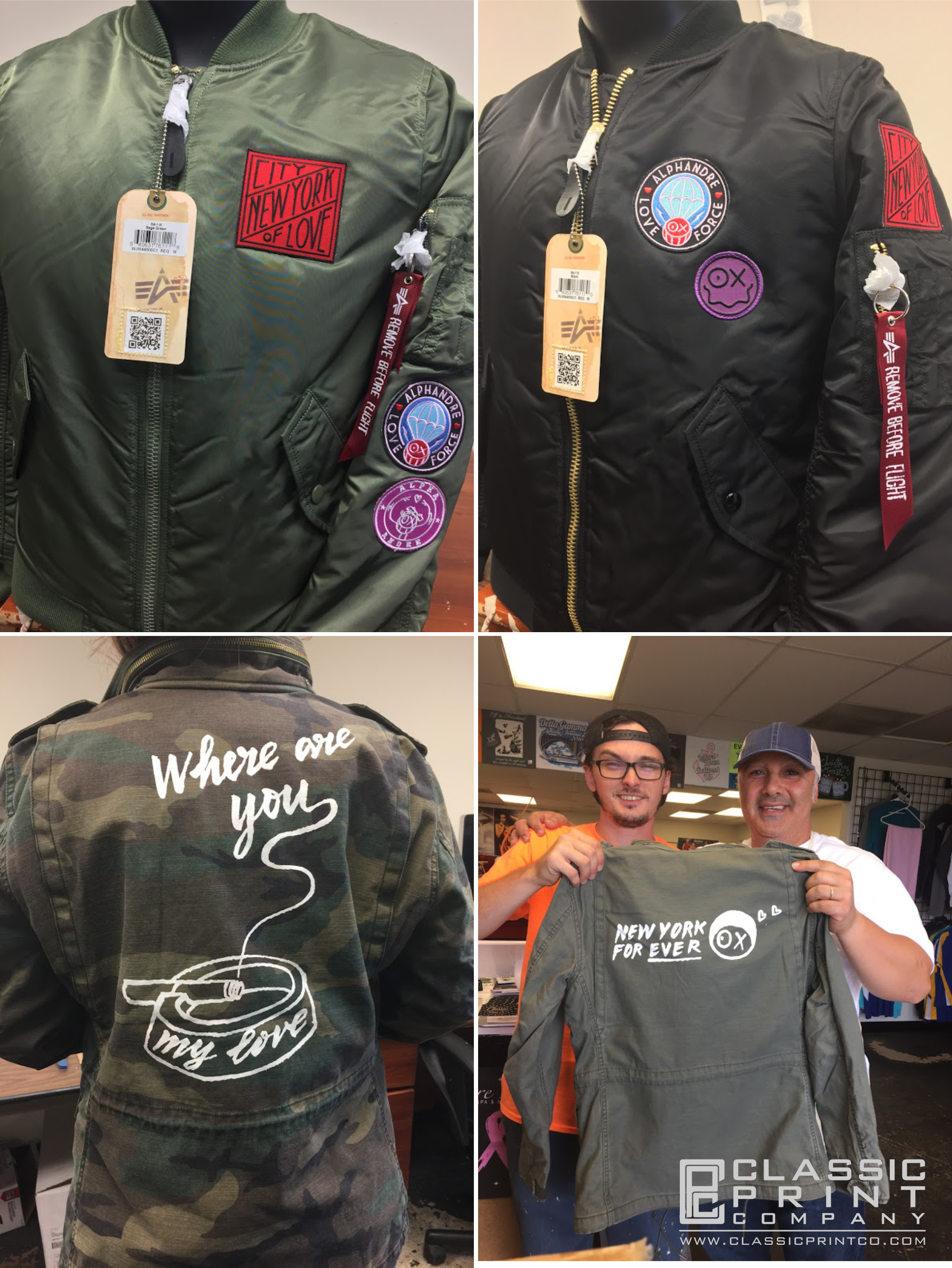

The client’s need: [I was] preparing retail-ready jackets for a very high-end retail store in New York called Barneys of NY. Project consisted of flight bomber jackets with custom patches and field jackets screen printed. The bomber jackets were puffy, reversible and needed custom patches going down both sleeves and the left chest. And we had to sew on custom labels. The field jackets came in different colors, including a camouflage pattern, and needed screen printing on the back.

The first process was artwork, digital layouts, approvals and then a spec sample to be shown to [the] client before any work actually started. Once this was done, then we moved on to producing thousands of patches and having them ready to be sewn on. At the same time, we prepped the screens for the field jackets.

The execution: Once everything was approved and we got the green light to start production, it was actually exciting. Jobs like this are what makes me enjoy my work. We had to hire some help to get the sewing done quicker. Sewing patches going down sleeves on a reversible puffy bomber jacket is no small task. The arms get narrower as you get closer to the hand opening—not to mention that the size small is even harder. Of course, the patches were done on … an embroidery machine, but sewing the patches on [each jacket] was all done by hand—one patch at a time, one jacket at a time, one by one. It was tricky, but we got it done.

The obstacles: Of course, it’s the job that you think is going to be easy that gives you issues. We had started printing the camouflage field jackets—about 80 of them—when I get a phone call to halt production on them. Apparently, the spec sample that I sent to my client that was approved had a dye migration issue that didn’t show up when we first printed them. Even my client—when they got the spec sample, [said] it was fine, but as it sat in their office, the darker brown camouflage print started bleeding through the white ink. Luckily, they saw it and called in just as we were printing them. We ended up adding a dye-migration blocker and then printing the white ink on top. This solved the problem of the dye migration.

The outcome and advice: The finished products made it to retail. [The] client was happy with the work. We delivered a retail-ready product. If there’s one thing I can recommend on custom projects like this, it would be to set the right expectations and in-hands date. Give yourself time to get the project done right. If you haven’t done something like this before, do a test run on an actual item so you see how long it takes to finish one piece. Time is money. Be careful [about] giving out prices too quickly. Do your homework first. Otherwise, it will cost you money. It’s also a good idea to keep a paper trail in case your client questions something. You can refer back to your email or quote and show them what you wrote. Lastly, always be wary of camouflage printed fabrics!

For details on how to participate in a future edition of Decoration Diaries and share your apparel decoration project success, email Amanda Cole at [email protected].